We Design & Build Custom Dining Tables

We build large custom dining tables, conference tables, and unique tables of all sizes.

It can be difficult to find a wood table that suits your space and style. We custom design to suit your space and coordinate with the style of your existing furniture or woodwork. We have built many extendable dining tables, which include space inside the table for storing the leafs when not in use.

If you need a table to seat 10, 12, or more people, a custom design may be just what you need. We work in a variety of hardwoods: walnut, oak, cherry, maple, etc. With our expert finishing techniques we can give you anything from a natural wood look to bold and artistic wood graining, or we can work to color match existing furniture or woodwork.

Each table we design and build is unique, see the photos below for a look into the design and build process.

Contact us today for your free consultation.

Contact Us Today

See a Custom Expandable Dining Table: Start to Finish

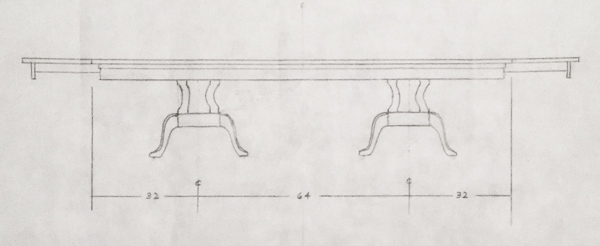

All of our custom dining tables start with a consultation and a hand drawn design.

We believe in using quality materials and our solid wood dining tables are constructed from quality hardwoods. The project begins with a stack of rough sawn, kiln-dried, hardwood. It has to be planed smooth and sorted for use in the table.

Rough sawn boards must be straightened on the jointer to prepare the edges for gluing and fitting. The jointer is the most dangerous machine in the shop.

One of the design elements in our dining tables is the wood grain itself. There is often a great deal of natural beauty in the graining of hardwoods. We carefully select boards to highlight the natural artistry of the materials. The planed boards for the table top are all laid out on a work bench and arranged to create a pleasing look for color, graining, and width of pieces.

The pieces are all numbered to keep the chosen pattern correct.

A large expandable dining table top must be glued up in sections, sanded smooth, and then the sections glued together to create the desired size. This is carefully planned work for an error can destroy hundreds of dollars worth of materials and labor.

For a pedestal table there is always a center support or ring that has to be tremendously strong. The challenge on this large table was to achieve the strength required while maintaining its beauty.

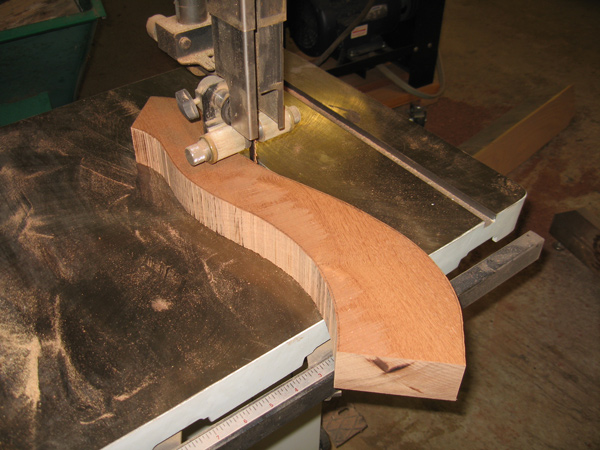

The legs for the pedestal dining table must appear elegant and yet be able to bear the weight of a heavy table top (300 pounds for this table). A hand drawn pattern is used to trace the legs. Then the heavy pieces are band sawed to rough out the shape. After this the curves are sanded with a special spindle sander and rubbed out by hand to even the curves.

The table under-framing has to be very sturdy to resist bowing or cracking under the constant pressure of the large expandable table top. We are thankful none of our table bases have ever failed.

We are also able to include handcrafted touches to many of our pieces. This table received a total of 78 hand-cut insets in its top, apron, leafs, and base. The insets are created by hand chiseling out squares from the face of the wood surface. Then a thin square of wood is set into the cut out at 45 degrees to the wood grain which was removed. This makes and elegant decorative touch unique to our work here at Old Virginia Woodoworking.

This table extends by means of a leaf on each end. The leafs are stored in a drawer in each end of the table. When in use the leaf is connected to the end of the table with hardware and supported with the drawer, for a unique expandable dining table design. Self-storing leafs are a big plus for keeping your table leafs in good condition as well as saving you storage space elsewhere.

The completed extendable dining table will serve this family for many years!