Custom Interior & Exterior Wood Doors

Unique custom wood doors add interest to your home and increase your curb appeal.

If you already have a design for an interior or exterior door we can give you a bid for building to your design. We can also draw up designs for custom wood doors to suit your needs.

3 great reasons to buy your custom exterior wood doors from Old Virginia Woodworking:

1) Strong & Durable

We assemble our custom doors with all doweled construction. Wood dowel construction is the strongest available method to make wood joints. We use the DowelMax system which typically places at least twice the number of dowels into major joints as other systems. Plus, the dowels we use with our system are made from solid wood that has been compressed. When glue moisture hits the compressed dowel it swells up in the drilled hole and becomes absolutely immovable. The only way to get these door joints apart is to shatter the wood.

2) Flat & Straight

We use multi-layered wood to build up our door rails. By gluing two or three or even four layers of wood we create door rails that are much more likely to remain straight and the door flat for decades to come. Our competitors rarely protect you with this type of effort. The custom wood doors we build are the strongest and most reliably flat you will buy anywhere.

3) Custom Door Thickness

We offer thicker doors than you may see on other sites. We can discuss with you the value and beauty of buying a heavy door for your application. We build doors 1-3/4” thick, 2-1/4 “ thick, 2-1/2” thick or more if you desire. We know what hinges to use and how to construct the jambs needed to support heavy doors.

4) Premium Quality Hardware & Weather Stripping

We know—four reasons is one more than we promised but …

We offer professional installation of the best door hardware and weather stripping system on the market—the Endura Trilennium line. We invested thousands of dollars to obtain the router guide and equipment to prepare doors for this quality hardware line. You can benefit from our expense very reasonably.

Follow along below to see how a custom wood door is designed and built, and then give us a call to talk about your project.

See a Custom Door Design: Start to Finish

The building of custom doors begins with drawing a pleasing design that highlights your existing architecture and woodwork.

Since each door is unique each project begins with creating a pattern to ensure the completed door will have accurate shape and fit. For this custom exterior door project we first had to create a pattern for the shape of the curved frame. That was obtained by tracing the existing opening unto eighth-inch hardboard.

Door Frame

When building a custom door we build the frame first to ensure a perfect fit of the completed door in the frame. Once the carefully checked pattern is made we use it to make the door frame.

This frame is made of two and a half inch thick African sapele wood. This exterior door required a curved peak at the top of the door. The curve was achieved by assembling a series of short blocks into a near-curve, gluing them up, and then the curve was cut in half across the peak to give two half-moon pieces. This allowed us to get the, still heavy, pieces up onto the bandsaw and to cut the curve to the patterned shape. The two large curved pieces were then sanded. After sanding they were re-glued to each other at the peak and glued and doweled to the tops of the side jambs. A ratcheting web strap was used to pull it all together.

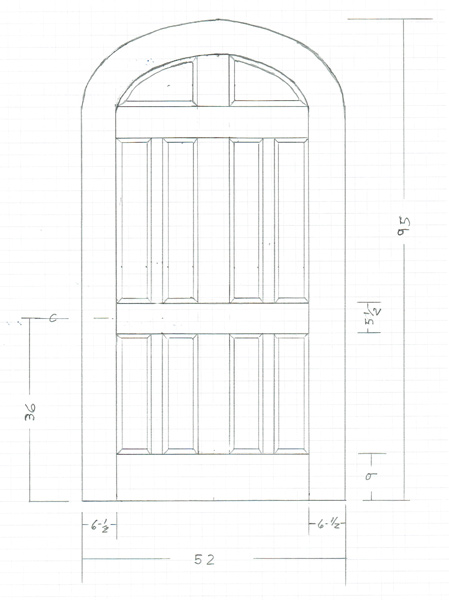

The Door

After the frame is complete the custom door can be made to fit the space. After making all the main frame pieces for this door, they were doweled with around 200 dowels and dry-fitted to make sure everything would fit together. Then a crew of three men glued the door, clamping it in two lifts to achieve final assembly. At two and a half inch thickness, eight feet tall, and a four feet four inches width, this substantial exterior door was too heavy for any individual to move alone once assembled.

Door Panels

Many custom exterior doors require panels to match surrounding architecture. Interior doors may need to match existing woodwork. This door was designed for a stone church building. The solid wood panels for this door were machined and inserted to give the raised panel effect.

The panels are actually a sandwich with solid wood outsides and a half inch of high r-value polystyrene in-between. This keeps the panels from developing frost in the inside of the door during cold months.

Door Installation

Due to the size and weight of some custom wood doors, the installation can be quite the project. In this case the door itself weighed around 300 pounds and required four men to lift and place on its four hinges. It fit great! We installed customized weather stripping to ensure the wind and weather stay outside where they belong. This door should be good for over a century!